Are you looking to add or increase leak detection capability on your pipeline?

You may be wondering what is involved and whether you are ready to move forward.

Some may be obvious, like determining whether you have the necessary instrumentation to support leak detection. But there are other considerations that may not be top of mind.

We have worked with several operators on a variety of systems. Based on our experience, our team has put together the following list of things to consider to help make sure you are successful.

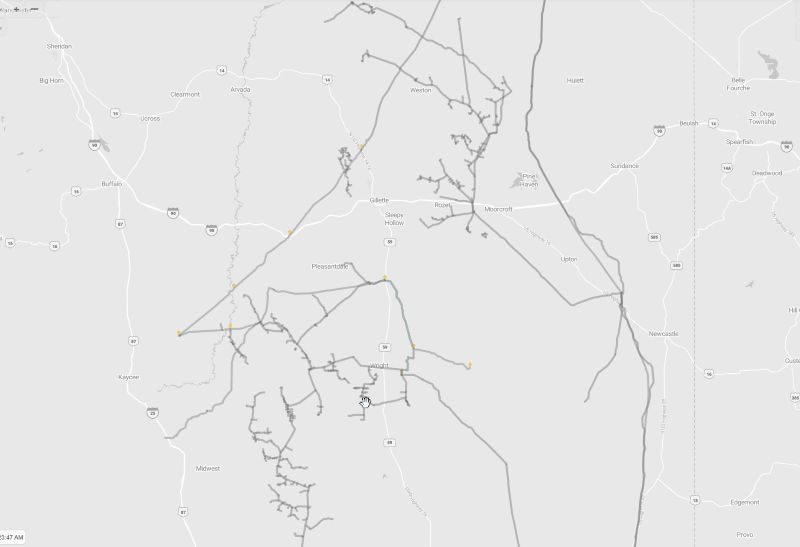

What kind of pipeline do you have? Is it a complex gathering network or a transmission line? This will influence several factors like what kind of data is available, how long the implementation may take, and how users will be trained.

Another factor in determining which methods of leak detection can be used on your line and the level of performance available is the input data.

What kind of meters do you have and where are they located? How accurate are they? How noisy is the data? Do you have pressure monitoring?

We strive to work with customers with data they have, but accurate and reliable measurement data is one of the largest factors driving performance in leak detection.

How will you view and manage alarms? Who will need access to the system? What will training look like for your team? These would be questions we would ask as we begin to work with you to implement your system and prepare your team to successfully use the system.